Transformer Winding Hot Spot Temperature Monitoring

Monitor oil-filled and cast resin transformers with EMI/RFI and high voltage environment immune fibre optic temperature sensors.

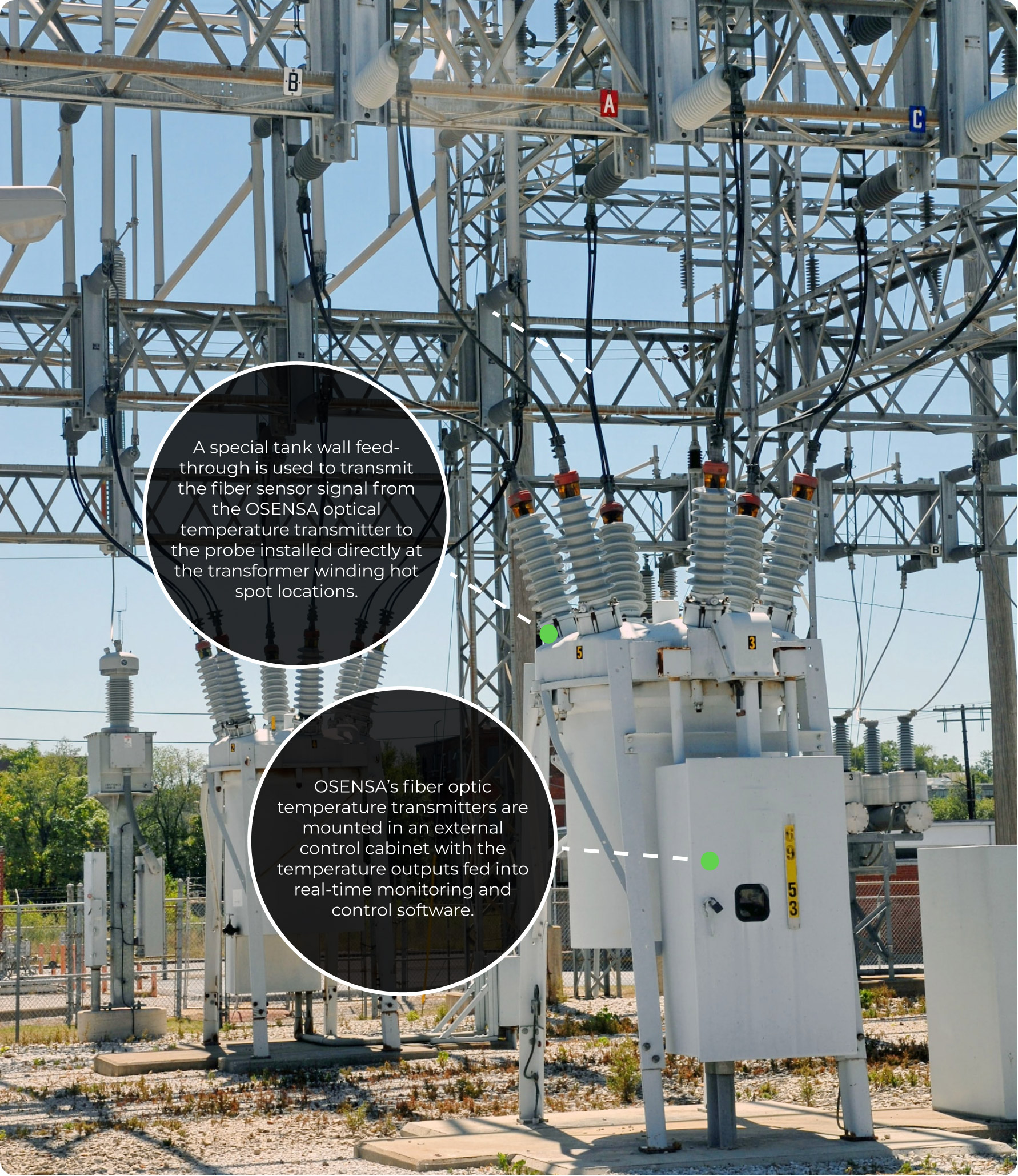

OSENSA's temperature sensors are completely immune to EMI/RFI and high-voltage environments making them ideal for transformer winding hot spot temperature monitoring. OSENSA has developed accurate, real-time, smart grid temperature monitoring solutions for power and distribution equipment.

Financial Significancy to Transmission & Distribution (T&D) companies

Fiber optic temperature sensors have been installed in high-voltage oil-filled transformers for over twenty years and are now considered the preferred method of transformer monitoring.

By monitoring temperatures at each transformer winding hot spot, utilities are able to operate the transformer at peak capacity, without extending into overload conditions that can dramatically reduce the life of the transformer.

Efficiency both in transmission throughput and service life can translate into savings of tens of thousands of dollars annually, making direct winding temperature sensing capability absolutely critical.

OSENSA’s Fiber Optic Temperature Sensing Technology

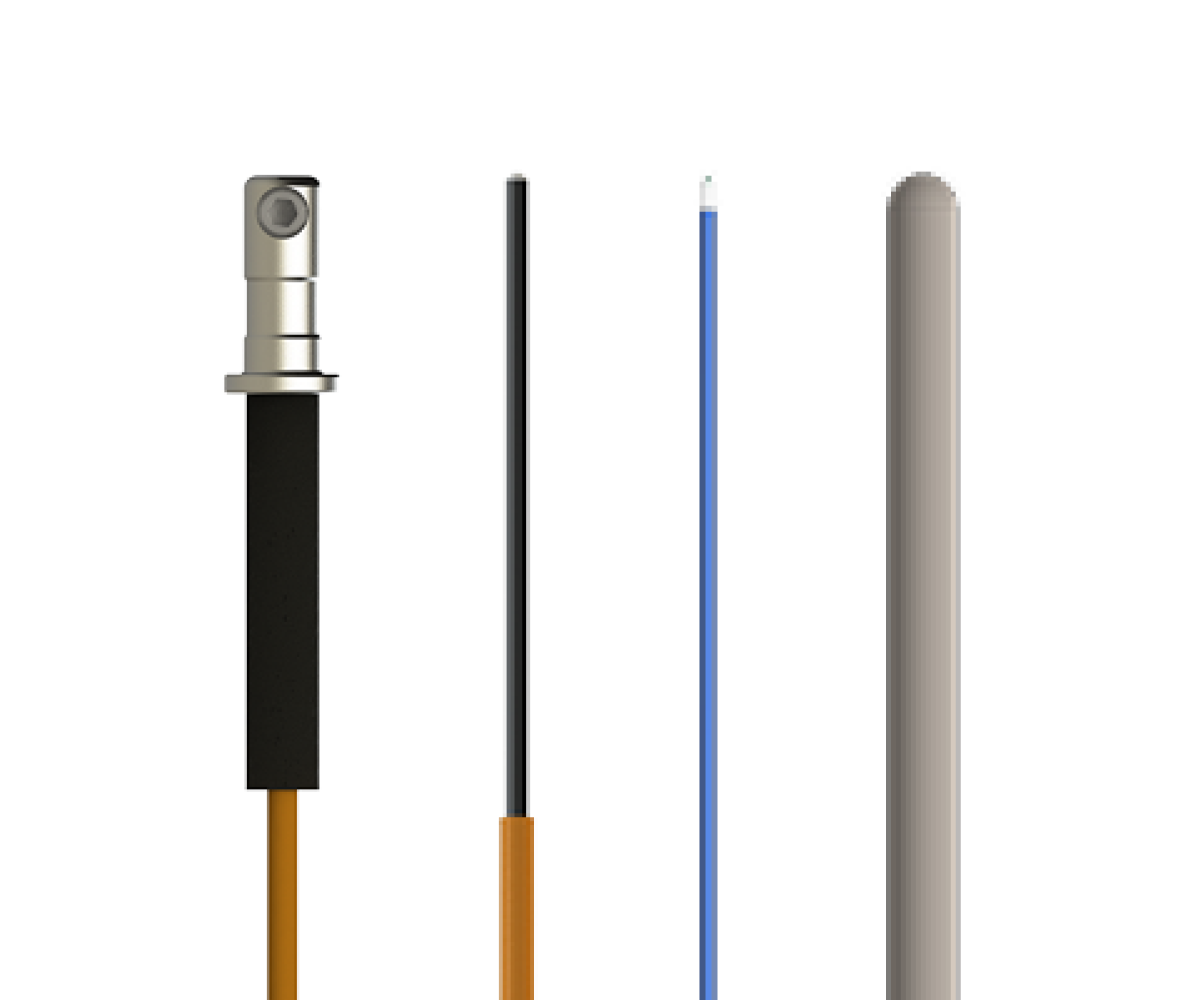

For oil-filled transformers, our fiber optic temperature probes are designed from high-dielectric strength materials such as Teflon and polyimide coated silica fiber so that they can withstand long-term immersion in transformer oil and kerosene desorption during manufacturing.