Switchgear Temperature Monitoring

Continuous real-time monitoring of switchgear temperature at critical contact points to quickly detect overload and fault conditions.

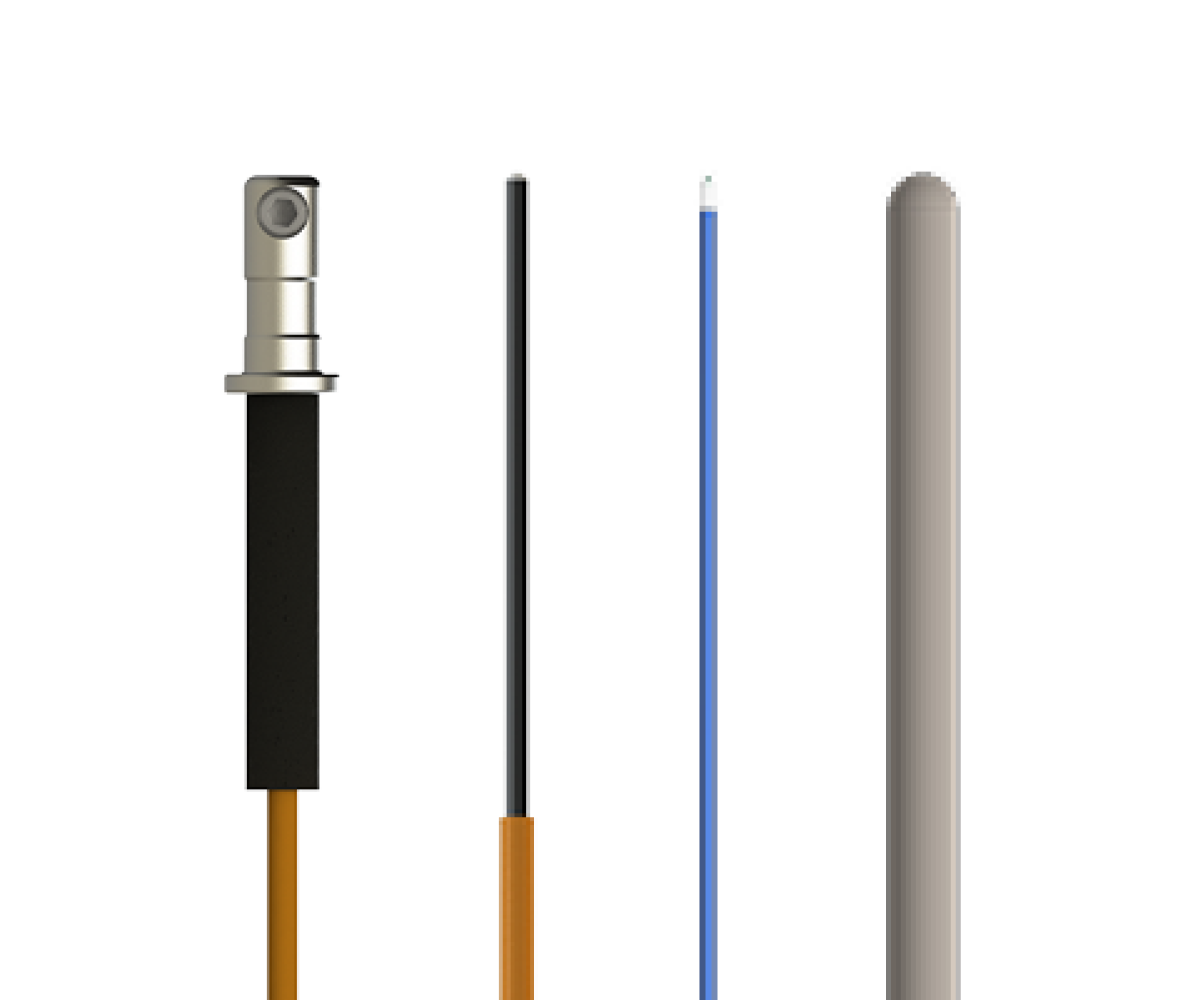

OSENSA is the industry leader in advanced fiber optic temperature monitoring specifically designed for switchgear applications. These technologies offer continuous real-time monitoring of switchgear temperature at critical contact points, enabling the quick detection of overload and fault conditions before catastrophic failures. The RS-485 Modbus communication capabilities of the system ensures seamless integration with any PLC/SCADA system and monitoring software. OSENSA's fiber optic sensors are immune to electromagnetic interference, making them ideal for mission critical switchgear applications.

Data centers and mission-critical operators demand thermal monitoring of their switchgears to ensure the reliability and safety of their operations.

Switchgears are essential components in electrical distribution systems, and undetected hot spots can lead to equipment failure, unplanned downtime, and even fire hazards. Continuous fiber optic thermal monitoring helps detect early signs of overheating, allowing for timely maintenance and preventing catastrophic failures. Additionally, maintaining optimal temperatures improves the efficiency and lifespan of the equipment, reducing operational costs and enhancing overall system performance

Fibre Optic Sensors vs Other Technologies

OSENSA’s fiber optic temperature sensors trumps the current cost-effective technologies available for high-voltage sensing applications.

Periodic IR Legacy Monitoring

Fiber optic continuous temperature sensing

Integration and Asset Management

OSENSA's products and software offer robust network and software capabilities designed to enhance monitoring and data management. The FTX series signal conditioners support both analog/digital output and RS-485 Modbus communication, ensuring seamless integration with existing PLC/SCADA and monitoring systems.

- OSENSAView software provides a user-friendly interface for configuring and monitoring multiple FTX series optical signal conditioners. It includes features such as real-time graphing, data logging, and advanced statistics, making it easy to visualize and analyze temperature data

- Remote Monitoring System (RMS) is specifically designed to collect, store, and visualize data fetched by OSENSA HMI or RTU hardware. RMS can be deployed on-premises as an stand-alone solution with no need for Internet connection (TCP/IP network connection required)."

What’s the Cost?

Maximize Your Data Center and Mission Critical facility's Efficiency with Partial Discharge & Fiber Optic Thermal Monitoring

Investing in a continuous partial discharge and fiber optic thermal monitoring system for your critical switchgear assets can yield significant returns within 6 months to 1 year. OSENSA's advance technology continuously monitors the temperature and PD events of critical components, helping to prevent equipment failures that can lead to costly downtime and repairs. Experience reduced maintenance costs and improved operational efficiency with our state-of-the-art partial discharge and fiber optic thermal monitoring solutions.

Switchgear Partial Discharge & Humidity Monitoring

Partial Discharge is a leading indicator of cable damage and insulation failure. PD magnitude is linked to the rate of deterioration.

OSENSA is the industry leader in advanced partial discharge monitoring specifically designed for switchgear applications. Ultra-high frequency (UHF) smart sensing and high-speed digital signal processing technology make it ideal for mission critical switchgear applications. OSENSA's small form-factor sensor detects partial discharge events in switchgear, bus ducts, and dry-type transformers.

Why Continuous Partial Discharge Monitoring Matters

Partial discharge (PD) is an early indicator of insulation degradation in medium and low voltage switchgear, bus ducts, and dry-type transformers.

Undetected PD activity can lead to catastrophic failures, unplanned downtime, and costly repairs. Traditional offline testing methods provide only a snapshot in time, leaving critical gaps in monitoring. Continuous partial discharge monitoring, using advanced UHF (Ultra-High Frequency) sensors, offers real-time insights into asset health, allowing for proactive maintenance and increased system reliability.

Introducing the PDX-800 UHF Partial Discharge Monitor

The PDX-800 from OSENSA is a state-of-the-art UHF Partial Discharge Monitoring System designed to provide real-time, continuous monitoring of switchgear and other electrical assets. It is engineered to detect and analyze PD events using high-speed digital signal processing and synchronized AC waveform analysis.

Advantages of Continuous Partial Discharge Monitoring

Use PDX-800 Continuous Partial Discharge Monitoring to Stay Ahead of the Electrical D-I-P-F Curve

Electrical D-I-P-F Curve

The PDX-800 from OSENSA Innovations provides real-time, continuous PD monitoring, helping organizations detect insulation issues early and take corrective action before failures occur. By integrating UHF sensors and advanced digital processing, the PDX-800 aligns with the D-I-P-F Curve to identify, track, and mitigate insulation degradation before it reaches a critical stage.

The D-I-P-F Curve represents the four key stages of electrical insulation degradation: Degradation, Incubation, Propagation, and Failure. This model helps engineers and maintenance teams understand how insulation deteriorates over time and the critical role of partial discharge (PD) monitoring in preventing catastrophic failures.