Motors & Generators Temperature Monitoring

Implementing reliable and affordable preventative maintenance strategies for critical industrial motors and generator assets is essential.

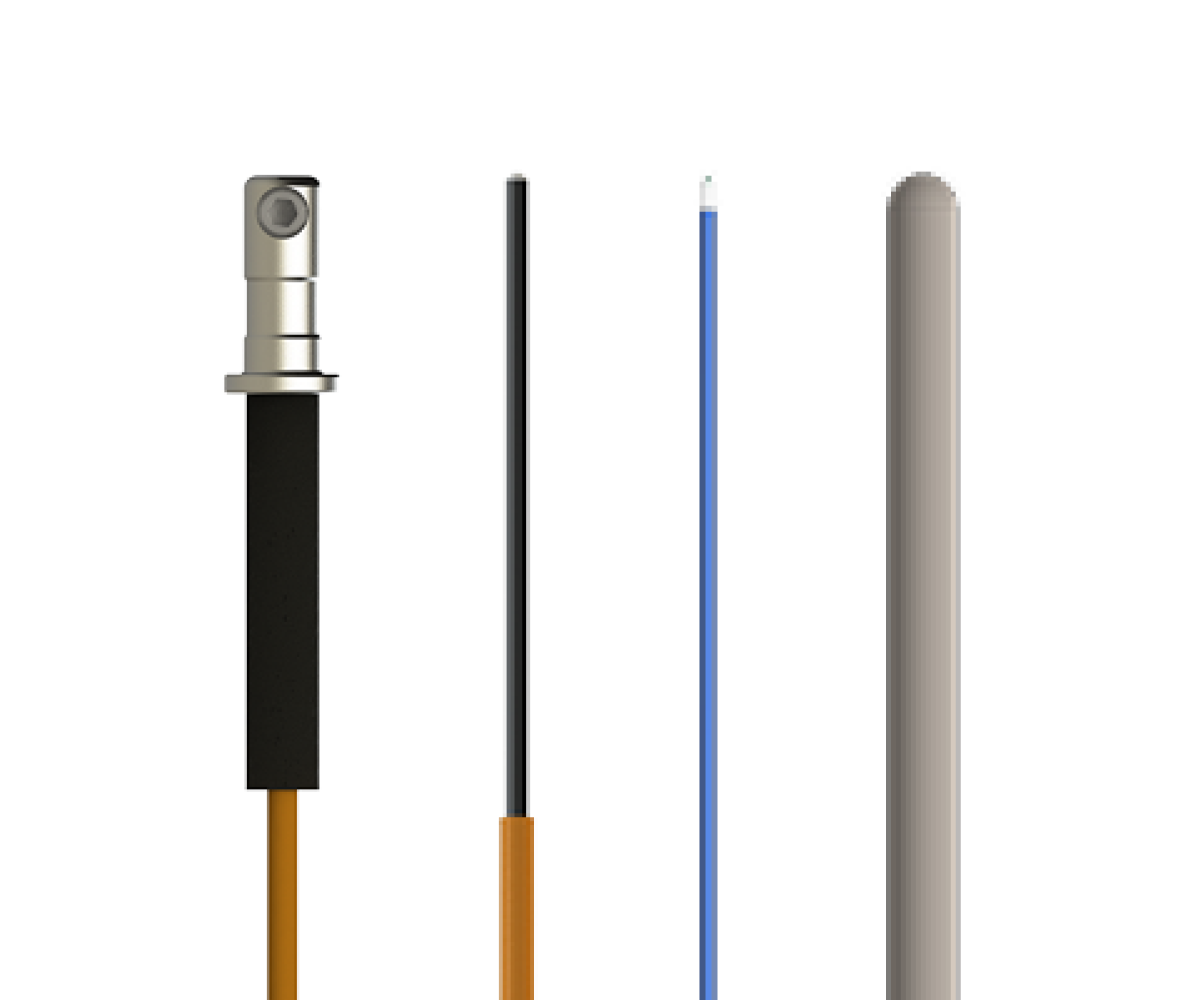

On-line fiber optic temperature monitoring is now commonplace for medium and high-voltage generator equipment. OSENSA’s fiber optic sensors offer a cost-effective solution for real-time temperature monitoring enabling equipment to operate at peak performance with extended service life.

Fiber optic temperature sensors are now routinely installed into large motor and power generator equipment to provide real-time monitoring and thermal protection of critical stator windings and bearing hot spots.

The safe operating temperature of rotating machine windings is limited by the heat which the insulating material can stand before eventual deterioration. This temperature and deterioration rate varies with different classes of insulating materials. Insulation deterioration at a given temperature is approximately proportional to the length of time that the temperature is above the critical threshold. Until recently, RTD’s (resistance temperature detectors) were typically embedded into windings to provide continuous monitoring, despite the inaccuracies caused by EMI/RFI interference. Now, OSENSA’s innovative technology has enabled the deployment of low-cost fiber optic temperature sensors.

Continuous Monitoring vs Legacy Monitoring

OSENSA’s continuous fibre optic temperature sensors trumps periodic IR Legacy Monitoring.

RF transmitter/ receiver sensors

IR Temperature Sensors

OSENSA’s fiber optic temperature sensors