DATA CENTERS + ENERGY

Fiber Optic and UHF Sensors

Continuous Thermal & Partial Discharge Monitoring

DATA CENTERS + ENERGY

Fiber Optic and UHF Sensors

Continuous Thermal & Partial Discharge Monitoring

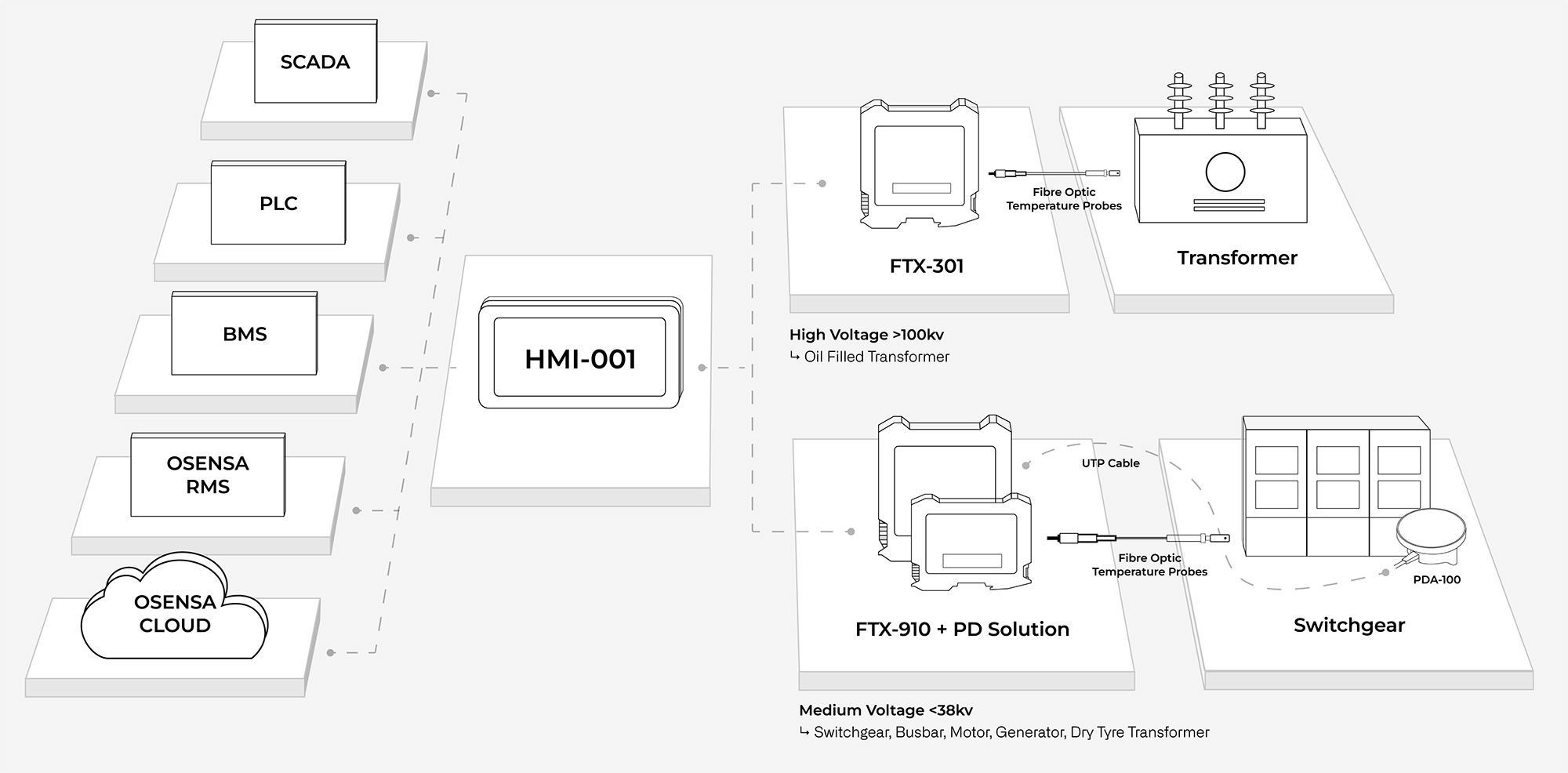

Our Solutions for the Data Centers + Energy Industry

Switchgear

OSENSA is the industry leader in advanced partial discharge and fiber optic temperature monitoring specifically designed for switchgear applications. These technologies offer continuous real-time monitoring of switchgear temperature and partial discharge events at critical contact points, enabling the quick detection of overload, fault conditions, and energy bursts from partial discharge events.

Oil Filled + Dry Type Transformer

OSENSA's temperature sensors are completely immune to EMI/RFI and high-voltage environments making them ideal for transformer winding hot spot temperature monitoring. OSENSA has developed accurate, real-time, smart grid temperature monitoring solutions for power and distribution equipment.

Motors & Generators

OSENSA offers advanced fiber optic temperature sensors tailored for motor and generator applications. These sensors provide continuous, real-time monitoring of critical components such as stator windings, circuit rings, and bearing hot spots.

E-Mobility

OSENSA’s advanced fiber optic temperature sensors provide the precision and durability needed to meet the challenges of the E-mobility industry, ensuring optimal performance and safety throughout the vehicle's lifecycle.

Switchgear / Oil Filled + DryType Transformer / Motors + Generators

Designed for Power

OSENSA's solutions are specifically designed to improve the reliability, safety, and efficiency of low and medium voltage electrical equipment, particularly switchgear, busbars, and transformers

8672 Commerce Ct.

Burnaby, BC, Canada V5A 4N7

Tel: 1-888-732-0016

(Toll-free Canada/USA)

1-604-259-7177 (International)

Copyright 2025 © OSENSA INNOVATIONS | Site Map