Induction Heating & Process Control

OSENSA’s temperature sensors ideally suited for induction heating applications due to their natural immunity to intense electromagnetic energy, high reliability, and fast response time.

Induction heaters and induction furnaces employ high-power alternating electromagnetic fields to rapidly heat electrically conducting objects. One example is barrel and in-mold induction heating for injection molding equipment. These heaters have operating frequencies between 5 to 100kHz and can consume 10 to 40kW of power.

Resources

Induction Heating Related Products

Temperature Transmitters

Highest accuracy, highest reliability, and lowest cost fiber optic temperature sensing solutions.

3 Ch, for High Temperature Only

2 Ch, for High Temperature Only

1 Ch, for High Temperature Only

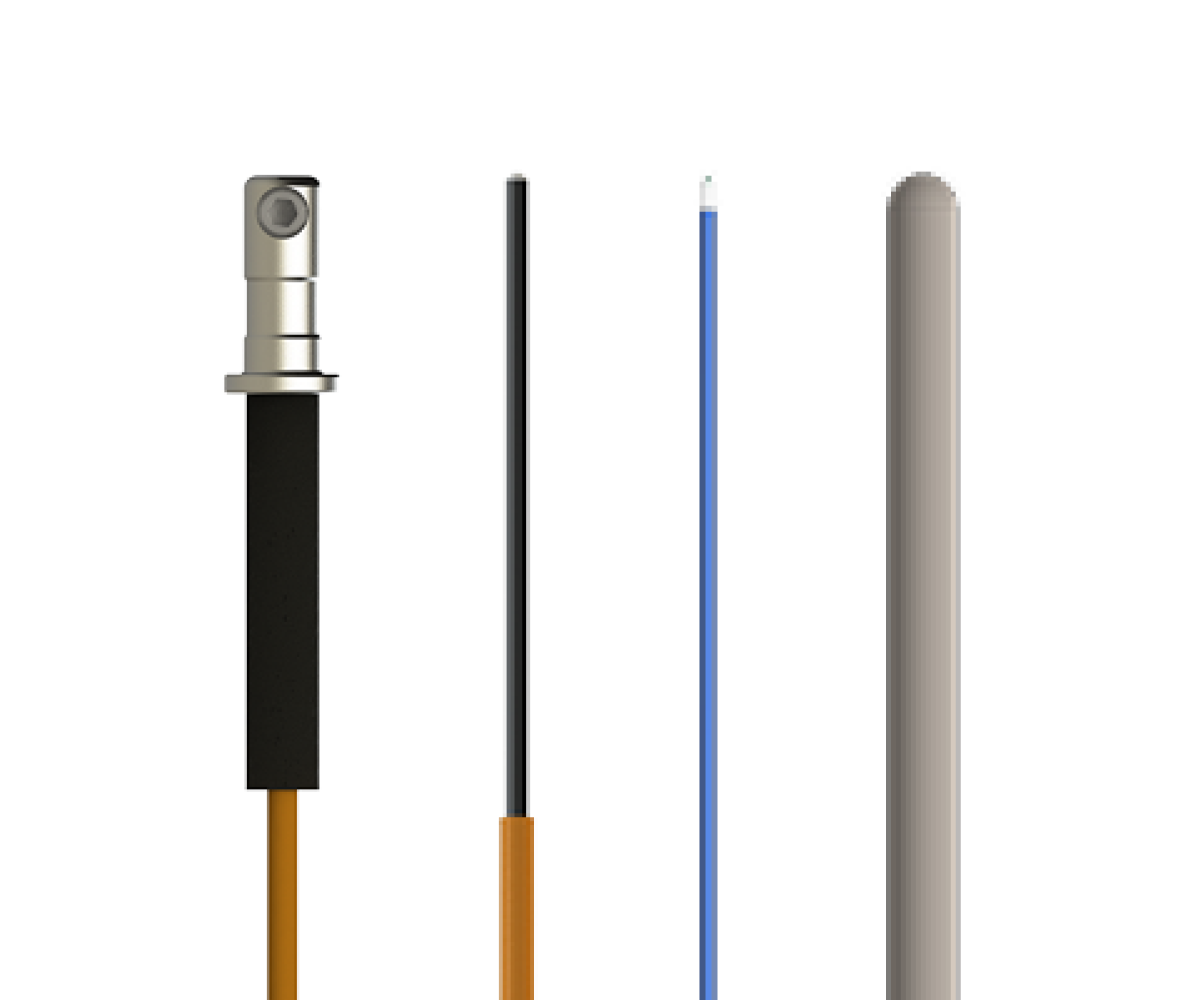

Temperature Probes

Electromagnetic radiation immune, high voltage, RF, magnetic field compatible fibre optic temperature probes.

5mm Alumina Ceramic, 1000µm GOF

0.45mm Polyimide, 200µm GOF