LIFE SCIENCES

Powered by Fibre Optics

MRI Research, Laser Ablation, HIFU & Phantom Studies

LIFE SCIENCES

Powered by Fibre Optics

MRI Research, Laser Ablation, HIFU & Phantom Studies

Our Solutions for the Life Sciences Industry

MRI

OSENSA offers single and multi-channel fiber temperature probes for MRI (magnetic resonance imaging), NMR (nuclear magnetic resonance imaging), and RF (radio frequency) environments, including low-cost disposable temperature probes with fast-response and exceptional accuracy.

Laser Ablation

OSENSA offers fiber optic temperature probes widely used in RF (Radiofrequency) and laser ablation surgeries to monitor and control tissue temperature, ensuring precise and safe procedures.

HIFU

By providing precise, continuous feedback, OSENSA’s fiber optic probes allow the treatment parameters (such as ultrasound intensity and focus location) to be adjusted dynamically, ensuring the target tissue receives the desired thermal effect without causing harm to neighboring tissues.

MRI / Laser Ablation / HIFU

Designed for Medical Research

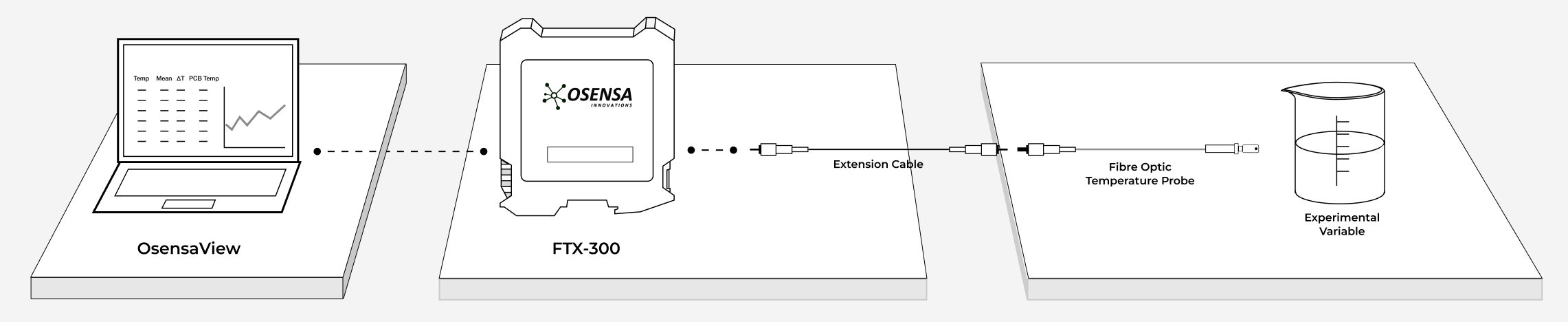

OSENSA supports research and development activities that require precise fiber optic temperature sensing solutions. OSENSA’s software and fiber optic probes can be customized and calibrated for a wide variety of laboratory and test applications.

8672 Commerce Ct.

Burnaby, BC, Canada V5A 4N7

Tel: 1-888-732-0016

(Toll-free Canada/USA)

1-604-259-7177 (International)

Copyright 2025 © OSENSA INNOVATIONS | Site Map