Microwave And Induction Heating Temperature Sensors

OSENSA's Fiber Optic Temperature Probes for Microwave Environments

OSENSA’s multi-channel fiber optic temperature sensors offer cost-effective microwave temperature monitoring of industrial processes including microwave assisted chemistry, microwave sterilization, and microwave sintering.

OSENSA’s multi-channel fiber optic temperature sensors offer cost-effective microwave temperature monitoring of industrial processes including microwave assisted chemistry, microwave sterilization, and microwave sintering.

OSENSA’s optical temperature probes for microwave environments are constructed from Teflon jacketing materials for maximum chemical and bio-compatibility, or from rugged stainless steel and high-temperature ceramics.

Fiber optic temperature sensors are inherently immune to microwave radiation and high-frequency electromagnetic radiation. Microwave environments where fiber optic temperature sensors are used include industrial microwave ovens for food processing and drying, microwave kilns for glass fusing, and paper, textile, or wood drying. Other applications include microwave sintering of ceramics and dental appliances, microwave sterilization, and microwave insecticidal treatment.

OSENSA develops fiber optic temperature probes that can be tailored for a variety of industrial microwave oven and microwave kiln applications. OSENSA's technology also permits short distance non-contact optical temperature measurement and can measure temperatures in excess of 400°C.

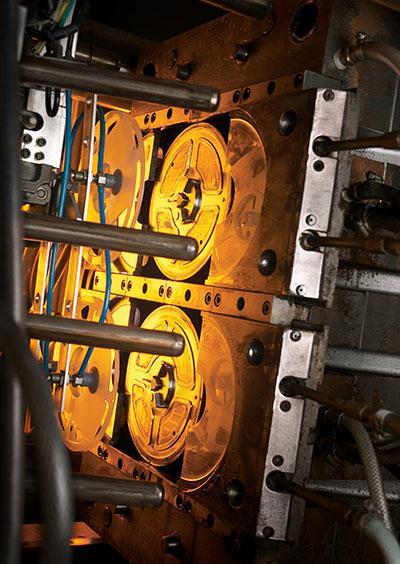

OSENSA's Fiber Optic Temperature Sensors for Induction Heating and Furnaces

Induction heaters and induction furnaces employ high-power alternating electromagnetic fields to rapidly heat electrically conducting objects. One example is barrel and in-mold induction heating for injection molding equipment. These heaters have operating frequencies between 5 to 100kHz and can consume 10 to 40kW of power. OSENSA’s industrial-grade fiber optic temperature sensors are ideally suited for these applications because of their natural immunity to intense electromagnetic energy, high reliability, and fast response time. OSENSA’s FTX series multi-channel temperature transmitters (signal conditioners) with 4-20mA analog outputs are easily integrated into injection molding process control equipment.